Posts

(January 26, 2017; Chicago, IL)

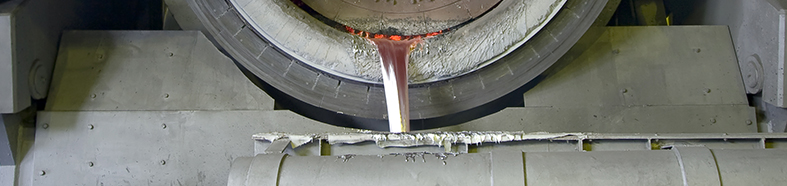

Plibrico Company, LLC offers a complete line of castable refractories and gun mixes for aluminum processing applications. From non-wetting to aluminum-resistant to phosphate-bonded castable refractories, Plibrico refractories are designed to withstand the environments in all aluminum furnaces like die-cast, reverbs and round tops as well as transfer equipment including troughs, launders and ladles.

Al-Tuff® Non-Wetting Refractories

Plibrico was the first to introduce a complete line of non-wetting aluminum contact castable refractories. The Al-Tuff series was designed specifically to provide an effective and economical solution for aluminum applications.

Al-Shield™ Aluminum Resistant Castable Refractories and Gun Mixes

Plibrico also offers Al-Shield castable refractories and gun mixes designed and engineered specifically for high-temperature and aggressive aluminum alloys and contact areas.

Phosphate-Bonded Refractories and Gun Mixes

Plibrico also has phosphate-bonded castables, gun mixes and plastic materials suitable for metal contact and all other areas in an aluminum furnace. Plibrico’s Exo-Set™ UNO series of castables and gun mixes are single component, “just add water” phosphate-bonded mixes for quick, easy and safe installation.

Plibrico Company LLC is a leading manufacturer and installer of superior aluminosilicate and high alumina monolithic refractories used in a variety of demanding thermal applications. For almost a century, Plibrico has focused on the research and development of complete turnkey refractory solutions. Headquartered in Chicago, Illinois, Plibrico has refractory construction contractors located throughout the United States and Canada, and supplies refractory materials worldwide through our PliPartner network of distributors and exporters.

For more information, please contact:

Plibrico Company LLC

Customer Service

(314) 981-2858

sales@hldev.plibrico.com

(July 5, 2016; Chicago, IL)

Plibrico Company, LLC recently developed PliShot Si-Bond B, a no-cement shotcrete refractory material that can withstand the highly-abrasive and alkaline corrosive environments of minerals processing. PliShot Si-Bond B was created to address some of the problems associated with the current no-cement shotcrete materials on the market today.

PliShot Si-Bond B simply mixes with water – no other caustic, temperature-sensitive aqueous materials are needed for mixing. Highly-durable, it is suitable for all industrial applications and can be easily installed in high-heat, high-alkali, high-abrasion environments. Trim time is improved for faster, easier installation.

To test its resilience, PliShot Si-Bond B was recently installed in the lower riser of a cement processing plant that produces 1.2 million tons of cement per year. The installation took place in a high-heat (24000 F), high-abrasion environment where coke, methane and other alternative fuels are burned creating an environment that is high in corrosive alkaline elements. Plibrico is pleased to report that after one year, the PliShot Si-Bond B material has virtually no visible wear. It has performed equal to similar materials used in this same application. Plibrico will continue monitoring the material’s service life.

Plibrico Company LLC is a leading manufacturer and installer of superior aluminosilicate and high alumina monolithic refractories used in a variety of demanding thermal applications. For over a century, Plibrico has focused on the research and development of complete turnkey refractory solutions. Headquartered in Chicago, Illinois, Plibrico has refractory construction contractors located throughout the United States and Canada, and supplies refractory materials worldwide through our group of distributors and exporters.

For more information on PliShot Si-Bond B no-cement shotcrete refractory material, please contact:

Plibrico Company LLC

Customer Service

(314) 981-2858

sales@hldev.plibrico.com

Plibrico Company, LLC

Plibrico Company, LLC Plibrico Company, LLC

Plibrico Company, LLC