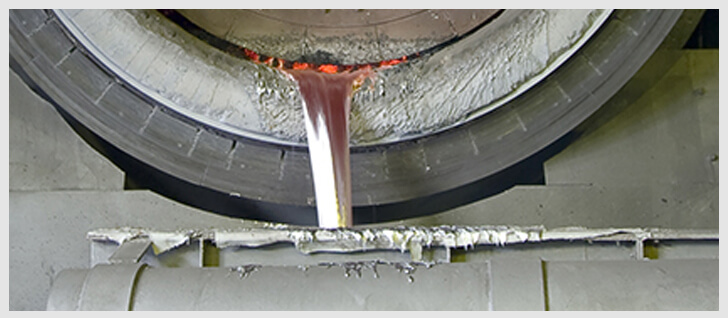

Refractory Products for Waste-to-Energy Incineration

Plibrico is a leading supplier of safe, reliable monolithic refractory materials for waste incineration applications including municipal waste-to-energy (WTE) and industrial waste incineration. Our refractory products are specifically designed to:

- provide efficient and easy heat transfer to boiler tube walls

- protect against the most abrasive and corrosive environments

- adapt to the demanding conditions needed to incinerate a variety of waste materials

- withstand the heat and chemicals associated with NOx to N2 conversion

- conform to all types of waste incinerators including moving and fixed grate, rotary kiln and fluidized bed incinerators

- help reduce downtime during unscheduled installation and maintenance with Plibrico’s exclusive Zero Lead Time Guarantee

Plibrico Refractory Products for Waste-to-Energy Incineration

Plibrico offers a full line of refractory materials for a variety of incineration processes. From thin to thick wall applications, Plibrico refractory products are designed to endure the most demanding environments, yet provide optimal heat transfer.

Plibrico’s Pligun® SiC HP8 refractory material is a high-purity, silicon carbide based gun mix that exhibits excellent thermal conductivity and abrasion resistance in waste incinerators. Our Plibrico® SiC 80 plastic refractory material offers similar benefits and can be installed in the most difficult of incinerator geometries.

Plibrico’s HyREZEST® brand of abrasion-resistant castable refractories and gun mixes are ideal for ash hoppers where thermal shock and abrasion occur at less elevated temperatures.

Contact your local Plibrico PliPartner today for a FREE evaluation of your waste-to-energy incineration system.

Plibrico Turnkey Refractory Solutions

Plibrico’s experienced team of refractory specialists, or PliPartners, provides complete turnkey solutions for your unique waste incineration application. From quality refractory materials to installation, repair and design services, our nationwide network of PliPartners are your single-source for reliable refractory solutions.

Quality Refractory Materials

Plibrico will analyze your operations and recommend the best refractory materials to meet your most demanding thermal requirements. Our stringent quality control policy ensures that our refractories will perform with excellence.

Zero Lead Time Guarantee

Plibrico is the only major refractory materials provider that offers a Zero Lead Time Guarantee – we will ship your material when you need it or your freight is FREE.

Construction and Engineering

Our refractory engineers will work with you to recommend the best solution for your unique challenge. And, you can count on Plibrico’s experienced installation and repair team to provide safe and efficient construction and maintenance services. We are committed to successfully completing your refractory project, no matter how large or small, on time and on budget.

Learn more about our construction and engineering services

Contact your local Plibrico PliPartner today to learn more about Plibrico’s refractory materials for mineral processing.